Bodor Laser Introduces the “Extreme Speed” Concept in Tube Processing, Launches the SK Series High-S

JINAN, China, Jan. 29, 2026 (GLOBE NEWSWIRE) -- Bodor Laser, a global manufacturer of laser cutting solutions, has announced the launch of its SK Series High-Speed Tube Laser Cutting Machine, alongside the introduction of its new “Extreme Speed” concept for tube processing. The concept focuses on improving overall manufacturing efficiency by combining high-speed performance, structural stability, and intelligent automation across the production process.

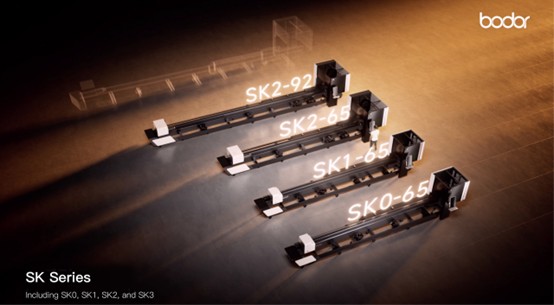

The Bodor Laser SK Series High-Speed Tube Laser Cutting Machine

The SK Series is designed to operate reliably under high-speed conditions, delivering a maximum acceleration of 2.7G and a maximum rotational speed of 260 r/min. The rear chuck reaches position in 2.5 seconds, supporting rapid tube positioning and continuous cutting. According to internal testing, the system achieves up to 1.8 times higher processing efficiency at 2.7G compared with operation at 1G.

Precision is maintained through a laser head Z-axis speed of up to 60 m/min, supported by an upgraded adaptive following algorithm that enables fast and accurate height adjustment during cutting. The system also supports simultaneous loading and cutting, reducing tube loading time to approximately 8 seconds and increasing overall processing efficiency by more than 20%.

To ensure stability at high speeds, the SK Series features Bodor Laser’s proprietary arch-bridge structure. The three-dimensional triangular transmission design optimizes force distribution during rapid motion, improving mechanical balance and long-term stability.

The chuck system is manufactured from high-strength alloy materials and treated with advanced heat processing. Compared with the previous generation, positioning accuracy has improved by over 20%. In addition, front-chuck over-travel technology enables dual-chuck clamping for long tubes, ensuring consistent accuracy throughout the entire cutting process.

Addressing the industry’s shift toward small-batch, high-mix production, the SK Series integrates an AI-based intelligent nesting system that automatically optimizes cutting paths. Compared with conventional nesting methods, the system increases cutting efficiency by up to 30% and improves material utilization, resulting in annual savings of more than 1,000 tubes under comprehensive production conditions.

Optional configurations—including zero-tail cutting, bevel cutting, and loading and unloading following support—allow the SK Series to be adapted to a wide range of advanced manufacturing requirements. With the Extreme Speed concept, Bodor Laser aims to set new benchmarks for efficiency and reliability in tube laser cutting.

A photo accompanying this announcement is available at https://www.globenewswire.com/NewsRoom/AttachmentNg/d9239c7d-69b3-4ac8-b2f1-4e628137ff79

Contacts

Bodor Laser

https://www.bodor.cn/

Jack Thompson

info@bodor.com

热门文章

L'ATELIER DE JOËL ROBUCHON HONG KONG 延续十八载辉煌传奇 今夏载誉回归置地廣塲

2025年TOURISE大奖揭晓:东京、纽约、安卡什与巴黎荣获首届殊荣

从“眼巴巴”到“手飒飒”,5年59次打破国外技术垄断——国家管网集团北京管道有限公司“红色劲旅自主维保突击队”攻坚实录

2025年度全国会计专业技术中级资格考试 (甘肃考区)报名公告

「全球能源循环计划」愿景发布 电池循环经济加速落地

品誉咨询——绩效破局:从 “效率优先” 到 “效能质变” 的管理范式革新